Key Features

List of key features of the BORWA ST 185 ROCK DRILL:

-

Greater performanceThe ST 185 drill will outperform its competitors, and this difference becomes more visible over time; as we estimate a lifespan of 24 months, compared to the 18 months generally offered in the market.

-

Safer toolThe drill is safer, less noisy and has been upgraded to improve safety and to safeguard the health of the RDO.

-

Noise levelThe ST 185 when tested by the CSIR produced 102.9 dB, compared to the standard SECO that produces 107dB, which has been known to increase significantly to illegal levels over time due to muffler damage.

-

MufflerOur patented riveted polyurethane muffler can be serviced without any cutting or welding. No internal air flow restrictions and no ice build-up occurs. Furthermore the muffler is extremely durable and long lasting with no nip points.

-

Cost effective DrillThe ST 185 is the most cost effective SECO type rock drill in Africa, which will have a positive financial impact on its purchaser. This is because of its lower purchasing cost and general life cycle costs.

-

Cost effective PartsThe ST 185's parts are significantly more cost effective and are of the highest quality; the reason being that our parts are forged and not cast.

-

Significantly lower maintenance costsLess maintenance is needed due to the quality of our parts, the low replacement cost of our parts; and the quicker turnaround times due to our muffler design.

-

Extreme Water savingsThe water control back head has significantly improved not only safety, but water wastage and water pumping costs. Aquarius platinum tested our drill and reported a water saving of 15%.

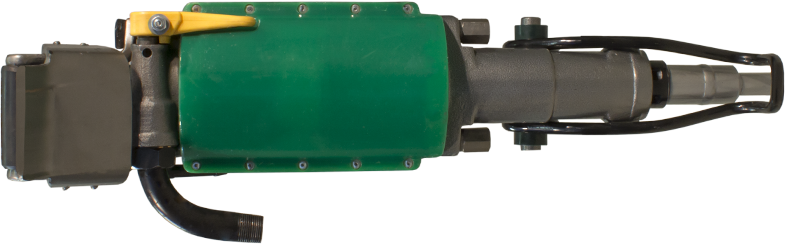

Product Description

The Borwa ST 185 rock drill was designed for African and South African mine conditions. The Borwa ST 185 has undergone a number of upgrades which are beneficial to both the owner and the Rock Drill Operator (RDO). Most of the upgrades listed have been patented and various tests have been conducted over years. The ST 185 Rock Drill is based on a SECO design similar to that of the Tranter S 215 rock drill. The benefit of this is that the Borwa ST 185 Rock Drill is 100% interchangeable with all SECO type drills.A. General

The Borwa ST 185 rock drill was designed for African and South African mine conditions. The Borwa ST 185 has undergone a number of upgrades which are beneficial to both the owner and the Rock Drill Operator "RDO". Most of the upgrades listed above have been patented and various tests have been conducted over years. The ST 185 Rock Drill is based on a SECO design similar to that of the Tranter S 215 rock drill. The benefit of this is that the Borwa ST 185 Rock Drill is 100 % interchangeable with all SECO type drills.

B. Safety

Safety is always the first consideration with any of the products of BMI. The issue of safety is considered an ever-greater priority as governments around the world are striving to make underground mining safer. The Borwa ST 185 complies with the highest safety standards in mining, which increase the level of holistic safety for miners underground thereby reducing the probability of fatalities, but more importantly decreasing the long term probability of disabilities and other ailments RDOs are exposed to.

Perhaps the most effective improvement on the ST 185 is its lowered sound of 102.9 dB (tested by the CSIR), as opposed to the industry average of 107 db. This innovative reduction in noise level will contribute to minimizing the long term hearing problems experienced by underground miners.

The ST 185 also has an improved rubber grip handle that dampens vibrations; and a hand guard that protects the RDO from crushing his hand in the event of an air leg rise, which is a common problem underground.

C. Performance

The ST 185 as a rock drill out-performs most SECO type drills, as it delivers superior torque, impact frequency as well as higher revolutions per minute. The ST 185, unlike any other SECO on the market is manufactured with forged steel and superior brass parts, all of which add to the durability of the product. Perhaps the biggest performance enhancer is our internationally patented muffler that eliminates ice from forming.

Icing is an often overlooked problem associated with underground rock drilling. The icing problem refers to a situation where water and air from the drill, moving at almost 6 L/second, causes the muffler to ice; thus preventing air flow from escaping the drill. This results in the slower performance of the drill, and the decreased productivity of the RDO in his shift. This problem is often exacerbated by the fact that RDOs, in their frustration in trying to make their call, attempt to dislodge the ice by often striking the muffler with a drill steal. This will result in permanent damage to the drill and the further lowering of its performance, as well as the accelerated wearing of its internal parts. The design of the Borwa ST 185 takes this into consideration and prevents this ice build-up. The industrial polyurethane compound and design of our muffler not only prevents ice build-up, but is also virtually impossible to dent or disfigure. The absence of icing means the RDO can drill more effectively without any interruptions.

D. Cost saving

The business of mining is essentially about producing an ounce of a commodity at the lowest cost; therefore cost efficiency is a competitive imperative for any mining house. Mining houses are price takers, therefore profits lie in efficiency and cost controls. In light of this, the Borwa ST 185 improves cost efficiency in the following ways:

- Improving the Life Cycle cost of the product. The Borwa ST 185 was designed to be a holistically cost effective tool. Therefore, the ST 185, its parts and its maintenance procedures are all extremely price competitive. Despite our competitive prices, the Borwa ST 185 does not compromise on quality or safety.

- Water pumping costs. The Borwa ST 185 also saves water and pumping costs, through its internationally patented back head that stops water flow when the drill is not in use. Mining houses are often remotely placed, where water and electricity are costly. Therefore mining houses must always consider water and pumping costs. The Borwa ST 185 back head can save up to 15% on water and pumping costs.

- Implementation costs. One of biggest problems with any new form of equipment is the cost associated with (a) training employees; (b) the implementation of the actual product; and (c) the cost of redundancy of existing equipment. When we were designing the drill, we chose to design a SECO-type drill because it is the most commonly used drill in Africa. The benefit of this is that no training is needed, as every RDO, and workshop is familiar with the nature and design of a SECO drill.

Conclusion

The Borwa ST 185 is an essential cost saving investment for any mining house with its superior drilling efficiency; lower life cycle cost; water saving abilities and cost effective implementation. When one combines this with the innovative financing solutions of Borwa Mining Instruments, a substantial cost saving opportunity exists that can improve the long term sustainability of one's mining operations.